RKV-16C

RKV-16C vertical cartoning machine operating in continuation mode, designed to guide the carton in a vertical position, allowing the product to be loaded from the top. It can stay in the cartoning machine integrated scale, which measures a given dose of the product in a carton.

-

- The machine works in continuation mode

- PLC control with color touch screen

- Automatic glue applicator

- Carton warehouse for 200 pcs. of cartons ~600 mm long, equipped with a drive and sensors for low and too low carton level

- Gluing cardboard boxes up and down using heated glue hoses

- Vacuum generator

- Carton guiding elements, including: nickel-plated chains, drive transmission elements, among others gears, shafts and spline bushings – galvanized,

- Cartoning machine working zones: taking carton, forming, gluing the bottom of the carton

- Manual packing in a safe zone (max. 8 people - 4 people per side) - to be determined

- Format change takes approximately 30-40 minutes by 1 mechanic and 1 operator

- Polycarbonate covers equipped with safety sensors

- Light and sound tower – 3 colors

- Plexiglass covers and doors with safety switches

- Smooth ejection of packed boxes using a belt conveyor

- Speed up to 50 cartons/min.

-

Dimensions CARTON WIDTH (mm) LENGTH (mm) HEIGHT (mm) Carton 150-300 180-360 50-150 -

Carton packaging process

Also see this

Tray Formers and Case Erectors

Packaging machines for forming four-flap cartons and trays.

Case Packer

Possibility of packaging and grouping many individual products into various cases.

Vertical packaging machines

A wide range of vertical packaging machines are designed for packing food and industrial products into bags.

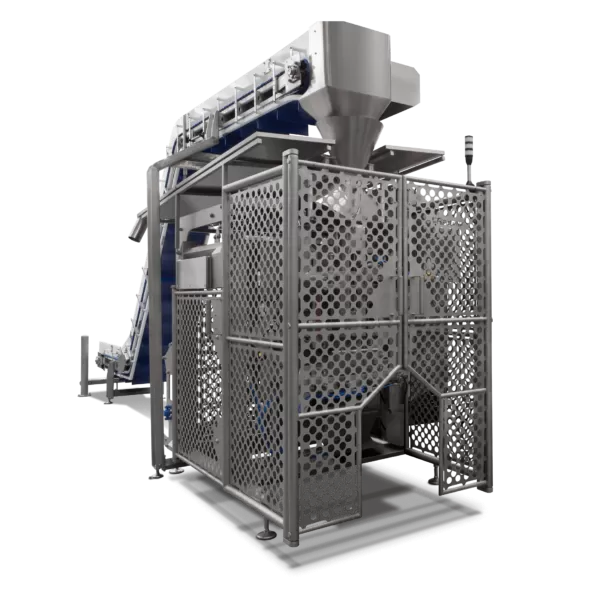

Dosing systems

Our dosing systems that are integrated with Vertical packaging machines. Their task is to weigh a given dose of the product into a plastic bag.