Case packing has never been easier. Discover the fascinating world of case packing systems by Radpak-fast, operator-friendly and reliable machines that will automate and grow your business.

Case packing

Our offer

Select a carton type to view applicable packaging machine models

Machine models for

| MODEL | MODE | DIMENSIONS | SPEED | Przejdź do strony maszyny | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| weight min/max | lenght min/max | height min/max | Constant heat version | Impulse heat version | ||||||

| RKZ-18NG | - |

80/200

|

200/400

|

140/200 |

25

|

- | ||||

| RKZ-22 | - |

115/300

|

200/400

|

180/300 |

18

|

- | ||||

| RKZ-27 | - |

170/400

|

200/400

|

180/320 |

12

|

- | ||||

| RKZ-22 | - |

110/300

|

250/300

|

130/200 |

18

|

- | ||||

| RKZ-27 | - |

140/300

|

240/400

|

150/300 |

12

|

- | ||||

| RKZ-18 | - |

80/200

|

200/400

|

140/200 |

20

|

- | ||||

| RKZ-22 | - |

115/300

|

200/400

|

180/300 |

18

|

- | ||||

| RKZ-27 | - |

170/600

|

200/400

|

180/350 |

12

|

- | ||||

| RKF-15T | - |

150/400

|

150/600

|

150/400 |

15

|

- | ||||

| RKF-25G | - |

150/400

|

150/600

|

150/400 |

25

|

- | ||||

| RGH-100 | - |

150/400

|

300/600

|

150/400 |

10

|

- | ||||

| RGZ-50 | - |

150/400

|

300/600

|

150/400 |

10

|

- | ||||

| RGZ-100 | - |

150/400

|

300/600

|

150/400 |

10

|

- | ||||

| RT-01 | - |

60/400

|

60/600

|

30/300 |

40

|

- | ||||

Automation of industrial processes is not only a significant time saving, but also the key to ensuring precision, repeatability and maximum production efficiency. RADPAK, a leader in the production of packaging machines, offers modern devices for bulk cartoning. This solution allows you to group individual products into various cases, meeting the expectations of companies from various industries. We encourage you to familiarize yourself with our offer!

Types of cases

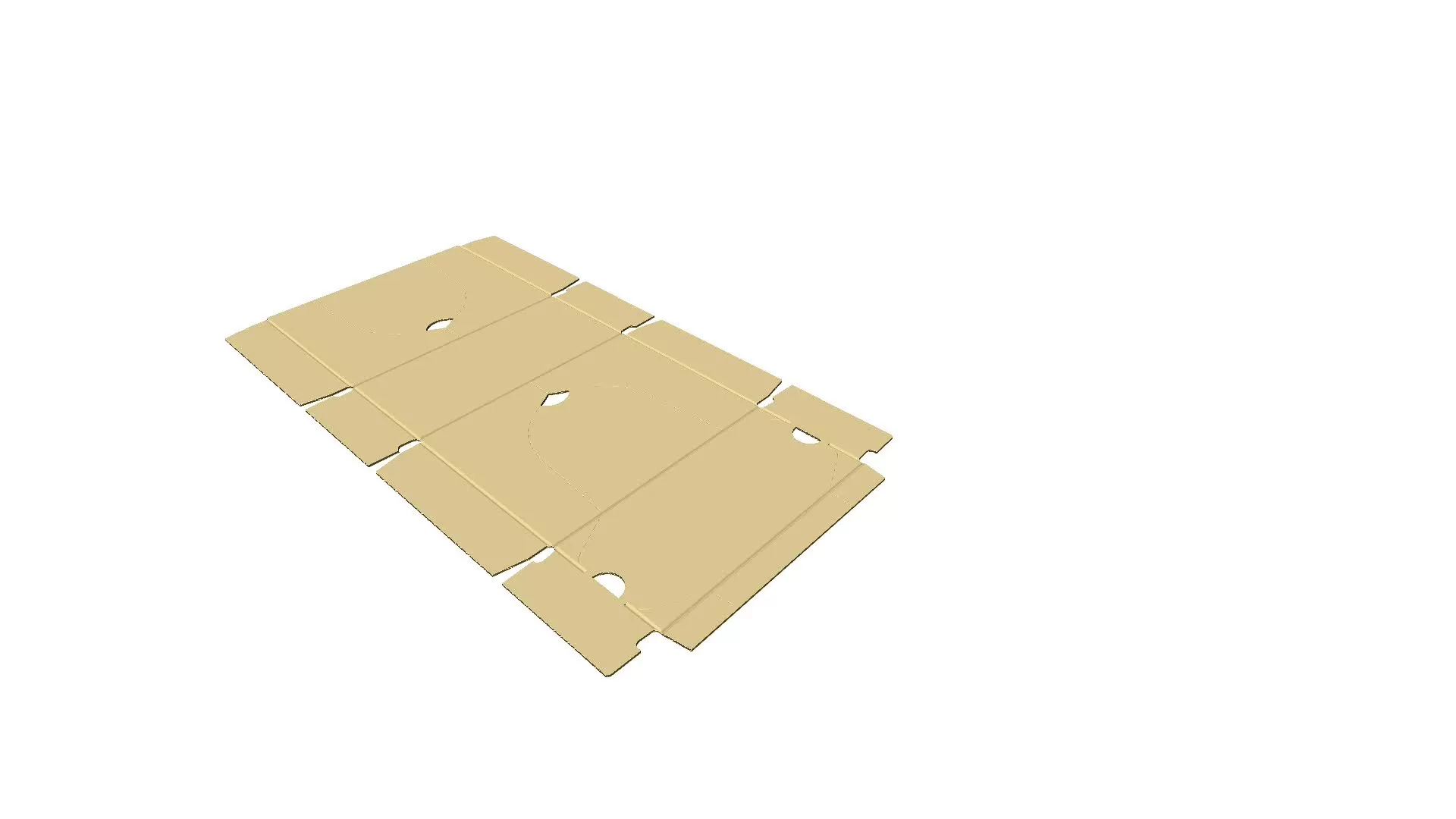

Wrap around case

A device that allows for forming wrap-around cardboard is the right choice for companies focusing on optimizing transport space. The flat cut cardboard is wrapped around a group of products, allowing for precise adjustment of the packaging to the contents. This solution not only increases load stability, but also minimizes material consumption.

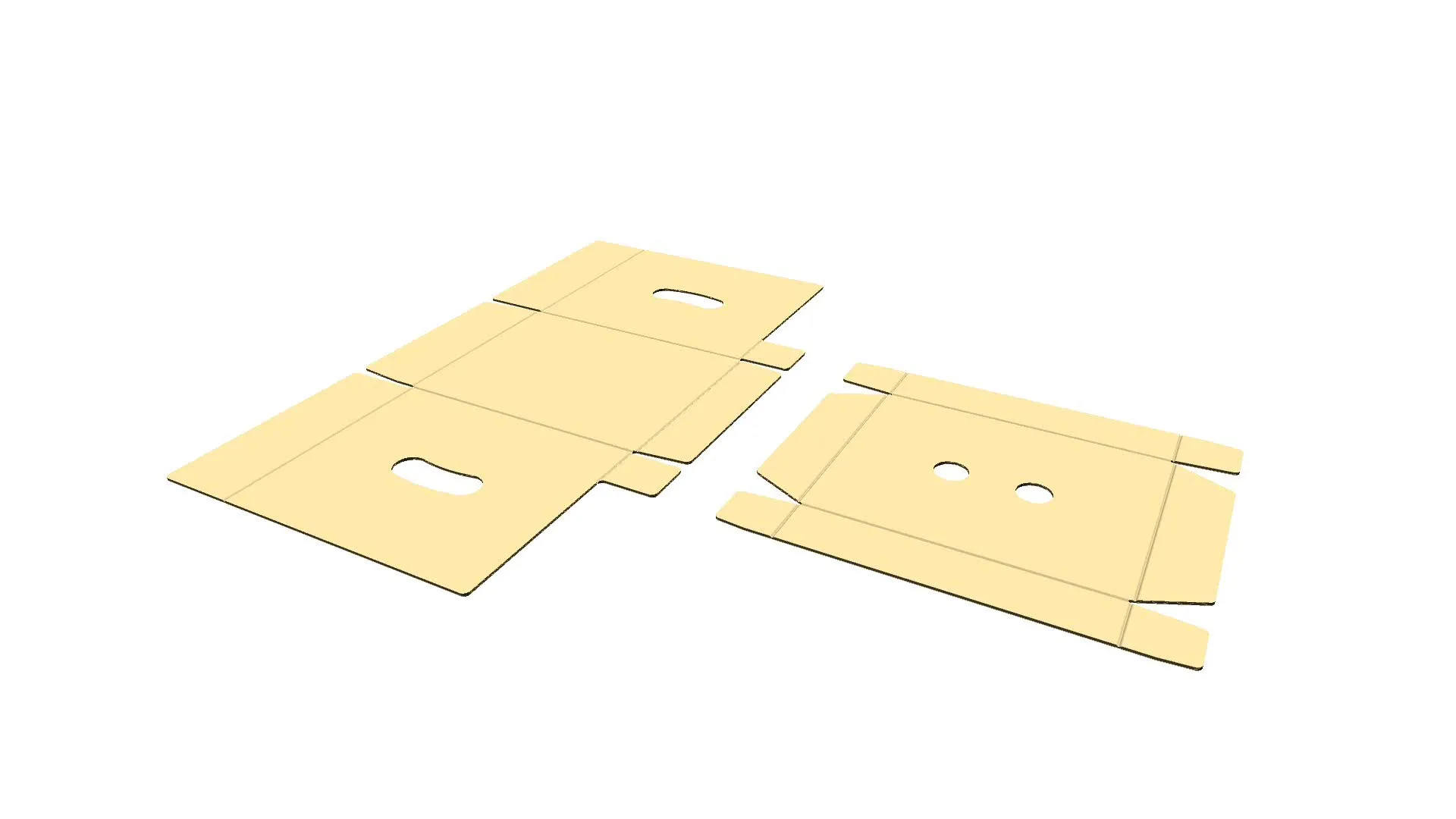

Tray&Hood case

The case with an outer cover ensures perfect product presentation on the store shelf. The collective cartoner forms a tray and applies a cover, creating aesthetic and functional packaging. This option is often used in industries where easy removal of the cover is important, e.g. the food industry.

Tray&Lid case

In this variant, the cover is inserted inside the tray, making it even more compact. The device enabling such packaging formation ensures great convenience of use, especially in places with limited storage space. Products are stored safely, and the ease of opening makes the packaging functional at every stage of distribution.

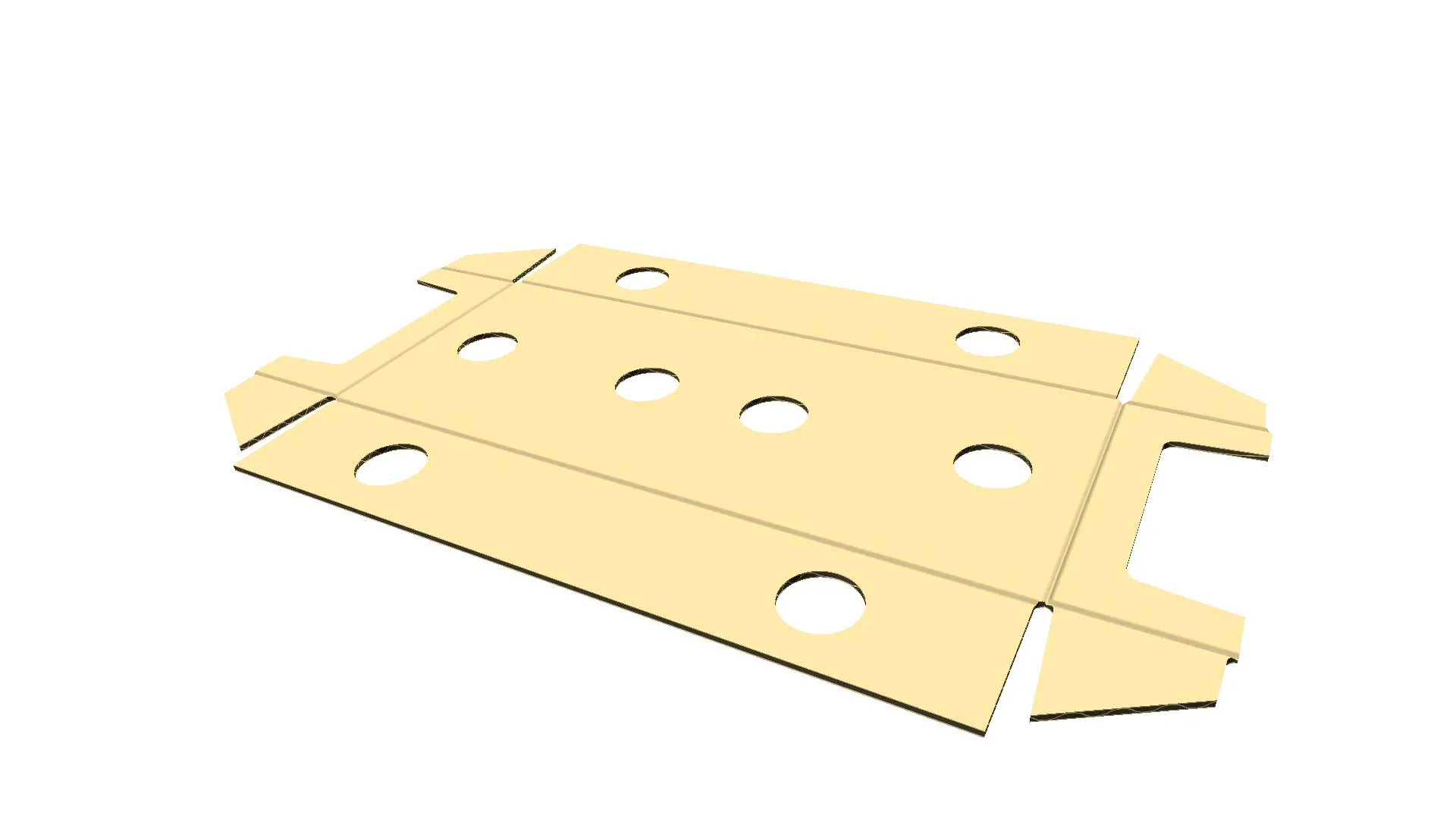

American box

The four-flap carton ensures simplicity and versatility in the packaging process. It can be quickly closed using adhesive tape and then filled manually or automatically. This is an ideal solution for transport and storage, guaranteeing stability and protection of individual products. Its versatility means that it can be used in many industries.

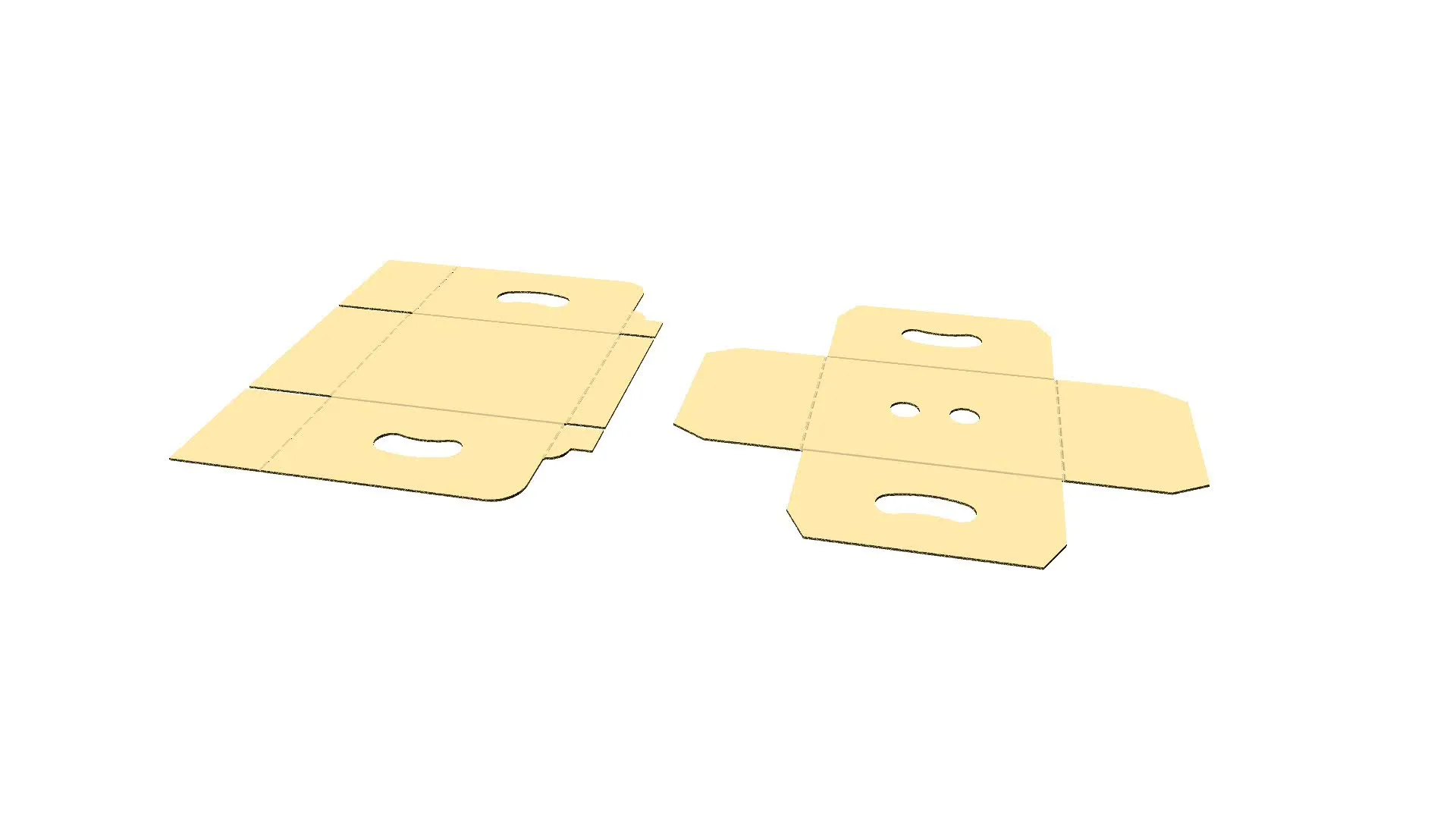

Tray

Automatically formed trays are extremely popular in the food and cosmetics industries. A machine designed for this purpose uses pneumatic suction cups to pick up the cardboard, then precisely shapes and glues its corners. This type of packaging is easy to use and aesthetically pleasing, which raises the standards of product presentation.

Why is it worth implementing case packaging?

Case packaging is a process that offers a number of advantages – from improving packaging efficiency and product protection to optimizing logistics and reducing operating costs.

Efficiency in the product packaging process

Bulk cartoning allows you to automate one of the most time-consuming stages of production. The inclusion of RADPAK machines in the process enables quick grouping of individual products and their packaging in various collective packages. Automating this task allows for higher efficiency and reducing the time needed to prepare products for transport.

Better protection for individual products

Collective packaging provides solid protection against mechanical damage, moisture and external factors. The design of such boxes allows for stable storage of products, regardless of the conditions in the warehouse or during transport. This minimizes losses resulting from damage, which translates into savings for the company.

Increased flexibility in customizing packaging

The ability to choose between different types of cartons, such as wrap-around or tray&hood, gives companies full control over adapting their packaging to specific requirements. Regardless of the type of product, bulk cartoning allows you to adjust the size, shape and function of the packaging to your specific needs.

Improving logistics and storage

The collective carton enables optimal use of space in the warehouse and in transport vehicles. In this way, companies can increase the efficiency of transporting more products with fewer trips. Precisely designed packaging also eliminates the problem of wasting space, which translates into reduced logistics costs.

Cooperation with RADPAK – reliable solutions for every production

Choosing our machines means, among other things, investing in advanced solutions that improve production processes, ensuring durability, efficiency and full technical support. Why is it worth trusting us?

A comprehensive approach to automation

RADPAK provides not only machines, but also technical support and advice at every stage of cooperation. Customers can count on training in the use of devices that will allow them to fully utilize their potential in everyday production. Thanks to this, the introduction of automation is smooth and without unnecessary downtime.

High quality machines

RADPAK products are characterized by reliability and durability. Investing in machines from this manufacturer is a guarantee of long-term operation while maintaining high efficiency. Precise workmanship and the use of modern technologies provide a competitive advantage in every industry.

Reduction of production costs

The implementation of RADPAK machines allows for a significant reduction in costs associated with manual packaging and losses resulting from inadequate product protection. Automating the product packaging process also reduces human errors, which further reduces operating costs.

Innovation and experience

RADPAK is a company with many years of experience that effectively combines practical knowledge with modern solutions in the design of packaging machines. The constant development of technology allows us to provide devices that meet current trends and growing market demands.

Cooperation with RADPAK is an investment in innovative technologies that not only improve production, but also help build a competitive advantage on the market. RADPAK is a partner you can rely on!