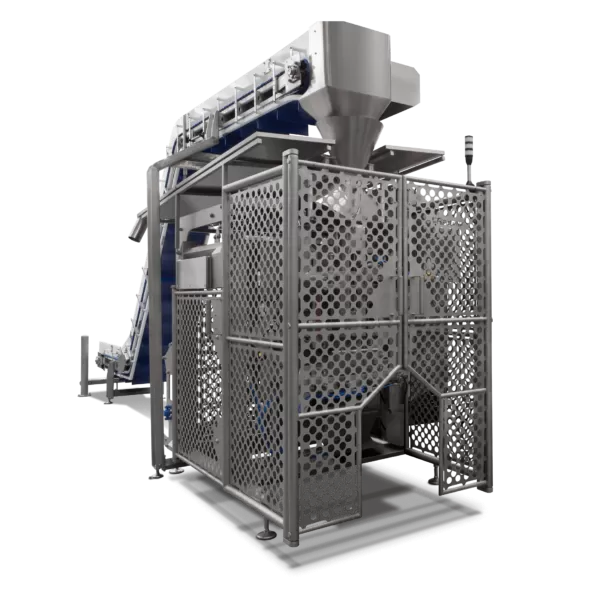

RGH-100

RGH-100 collective cartoning system, which has three main stations: unfolding the carton and closing the bottom, grouping and loading the product, and closing and sealing the top and bottom of the carton with tape.

-

- Forming a four-flap carton from pre-glued cardboard

- The time needed to convert the machine to a different format is approximately 40-60 minutes

- The machine is adapted to the following types of collective cartons - four-flap carton FEFCO 0201

- Index carton feeder with stations: feeding, filling, forming and closing the carton

- Vacuum generator for picking up cartons from the warehouse

- PLC control with color touch panel

- Two heads applying self-adhesive tape

- Polycarbonate covers and doors with limit sensors

- Capacity up to 6 cartons/min.

Grouping system:

- A section of shooting conveyors feeding the product at the appropriate speed to the grouping system

- Grouping system: placing individual products vertically on the longer side and counting them via an index conveyor with a servo drive

- Pushing products from the index conveyor through a servo-driven arm and placing a layer of product on the elevator

- Creating a full product group on the elevator

- Pushing product groups out of the elevator via a servo-driven mechanism

Cartoning system:

- Retrieving four-flap cartons from the warehouse using an electric arm with vacuum suction cups

- Moving a group of products into a pre-formed carton with a servo-driven arm

- Closing the box flaps while moving

- Dispensing cartons from chain carriers to a set of conveyors

- Seal the carton with adhesive tape while the carton is moving

- Dispatching finished cartons from the cartoning machine to the receiving conveyor

-

Box dimensions CARTON WIDTH (mm) LENGTH (mm) HEIGHT (mm) American box 150-400 300-600 150-400 -

Packing process in a four-flap carton

Also see this

Tray Formers and Case Erectors

Packaging machines for forming four-flap cartons and trays.

Cartoners

Cartoning machines can be divided into horizontal (the product is loaded sideways into the carton) and vertical cartoning machines (the product is loaded from the top).

Vertical packaging machines

A wide range of vertical packaging machines are designed for packing food and industrial products into bags.

Dosing systems

Our dosing systems that are integrated with Vertical packaging machines. Their task is to weigh a given dose of the product into a plastic bag.