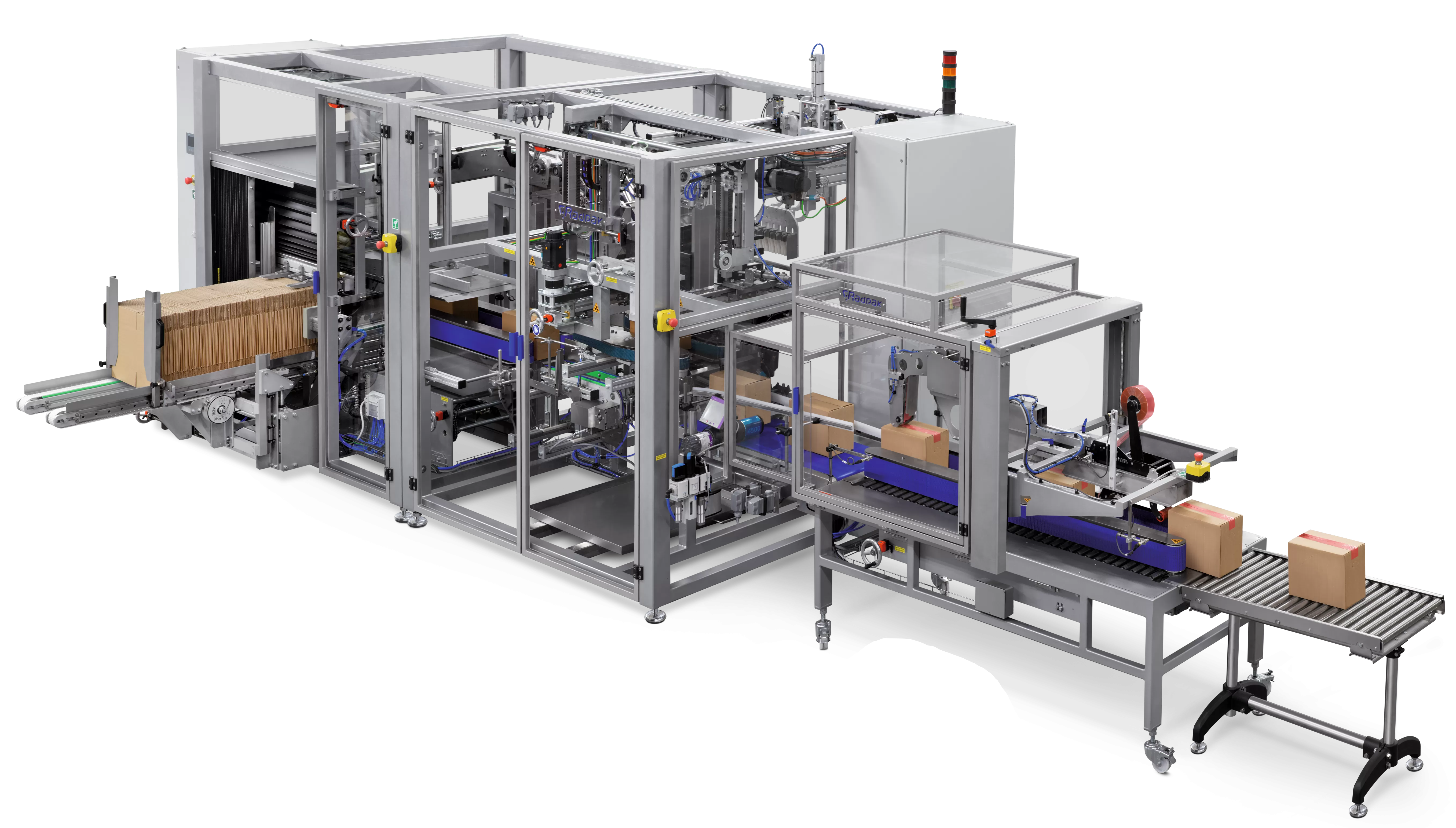

RGZ-100

The RGZ-100 machine has automatic counting and grouping system unit packaging using an index servo conveyor.

Unit products are pushed out from the index conveyor and placed on a servo-driven trapdoor. Once a group of products is created, they are inserted from the top of the carton.

There is in the device automatic positioning system for four-flap cartons under the trapdoor, which shortens the transport of the product to the carton and allows for more precise arrangement of the products.

-

- PLC control with color touch panel

- Polycarbonate covers and doors with limit sensors

- FESTO pneumatics

- SICK sensors

- The time needed to convert the machine to a different format is approximately 40-60 minutes,

- The machine is adapted to the following types of collective cartons - four-flap carton FEFCO 0201

- Light and sound column

- E-stop safety switches located on the machine structure

- Capacity up to 10 cartons/min.

Grouping system:

- A section of shooting conveyors with drives feeding the product at the appropriate speed to the grouping system

- Grouping system: placing individual products vertically and counting them via an index conveyor with a servo drive

- Pushing products from the index conveyor through a servo-driven arm and placing the product on a servo-driven trapdoor

- Creating a full product group on the trap door

- Introducing product groups from the trapdoor via a servo-driven mechanism from the top of the carton

Cartoning system:

- System for automatic reception of unfolded and glued four-flap cartons from the four-flap carton forming machine and positioning them under the counting and product introduction zone

- Automatic positioning of four-flap cartons under the trapdoor - an elevator for cartons that shortens the route of introducing the product into the carton

- Introducing a group of products into a pre-formed and bottom-sealed four-flap carton

- Automatic system for transferring packed cartons to the sealer

-

Carton dimensions CARTON WIDTH (mm) LENGTH (mm) HEIGHT (mm) American box 150-400 300-600 150-400 -

Packing process in a four-flap carton

Also see this

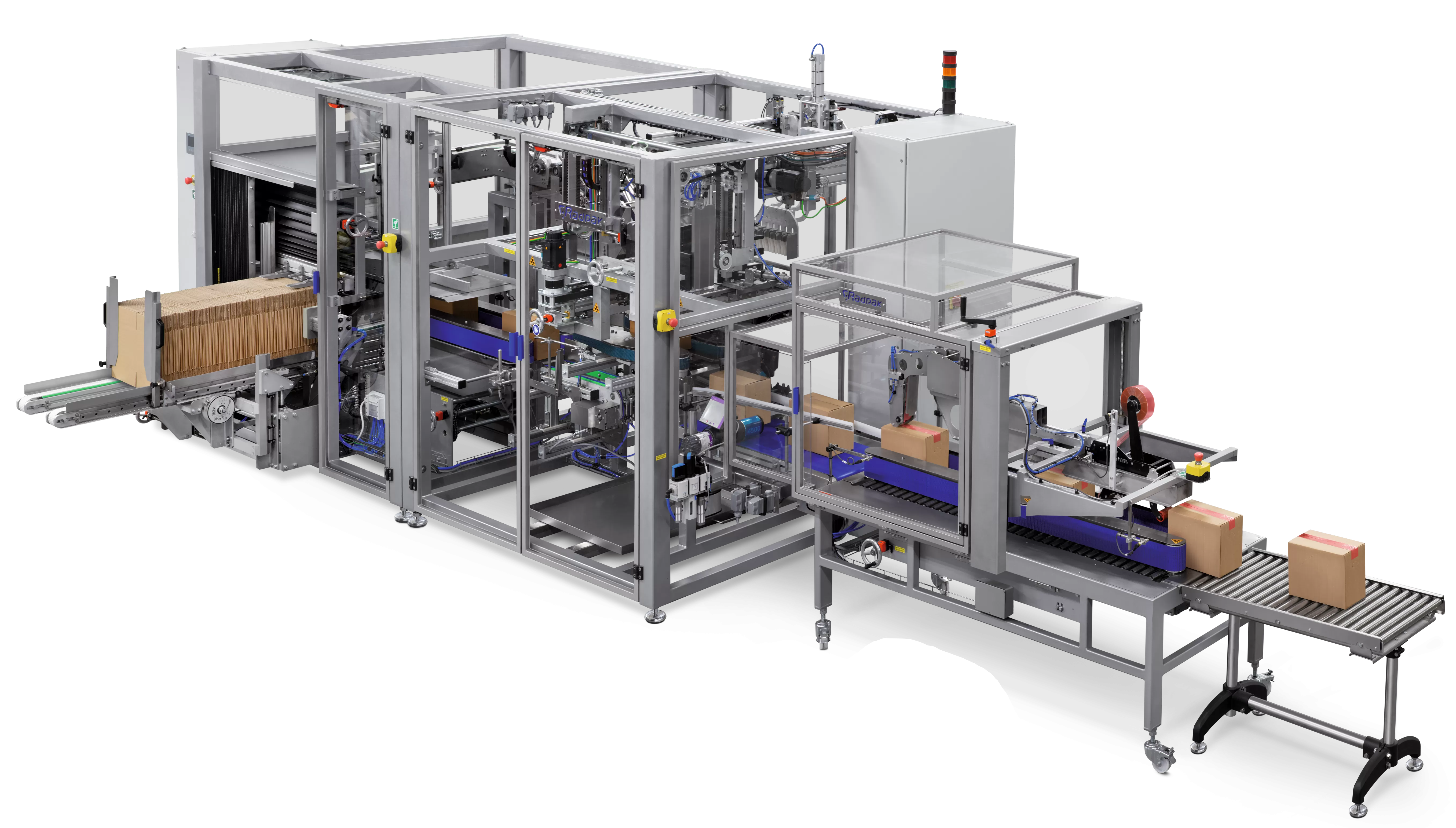

Tray Formers and Case Erectors

Packaging machines for forming four-flap cartons and trays.

Cartoners

Cartoning machines can be divided into horizontal (the product is loaded sideways into the carton) and vertical cartoning machines (the product is loaded from the top).

Vertical packaging machines

A wide range of vertical packaging machines are designed for packing food and industrial products into bags.

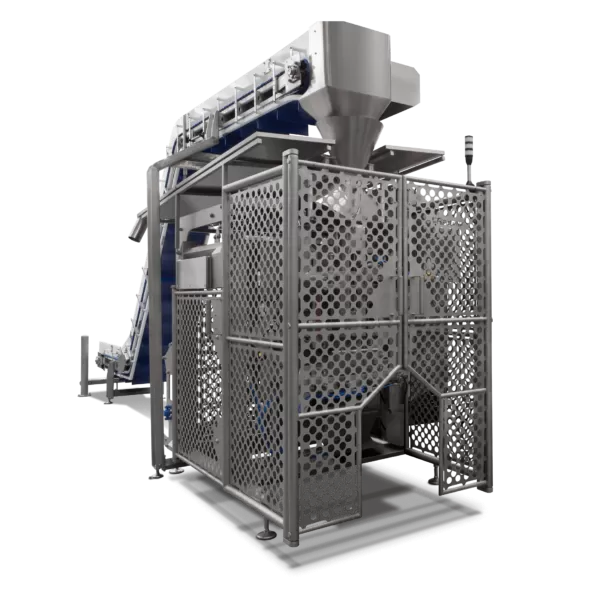

Dosing systems

Our dosing systems that are integrated with Vertical packaging machines. Their task is to weigh a given dose of the product into a plastic bag.