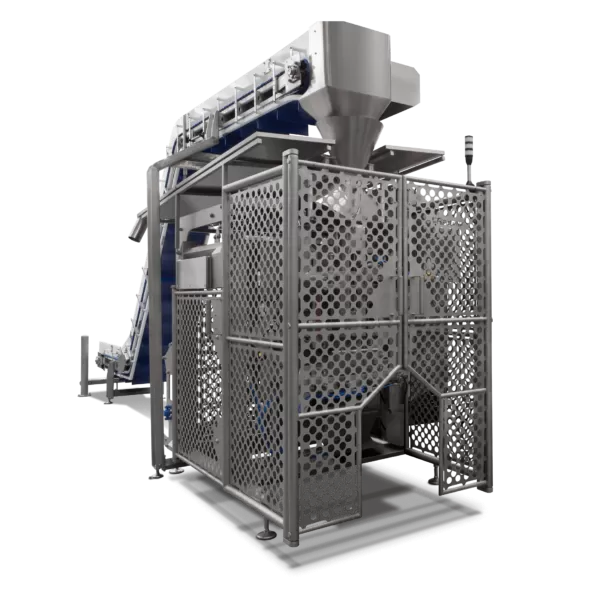

RKZ-22

The machine forms tray and lid cases from flat cardboard blanks , which are then glued and sealedwith the product inside.

The task of the tray and lid case packaging system is to count the required number of products and pack them in a specific configuration into a pre-formed case.

-

- Forming tray and lid and open tray cases from flat cardboard blanks

- Two carton magazines for manual replenishing of the blanks, length of the carton magazine ~800 mm, equipped in independently powered belts ensuring correct carton position in the magazine and feeding of the cases and sensors for low and too low blanks level in the magazine

- Index carton feeder with stations: feeding, filling, forming and closing the case

- Vacuum generator for feeding blanks from the carton magazine

- Nordson ProBlue Flex hot melt glue applicator with heated gluing guns

- PLC control with touch panel on swing arm (Allen Bradley, Siemens, Schneider)

- FESTO pneumatics

- SICK sensors

- Speed up to 18 cases/min.

Grouping system:

- Shooting conveyors feeding the product into the case packer at correct speed

- Grouping system: placing individual products vertically and counting them via a single index conveyor

- Pushing the product from the index conveyor in the desired quantity and creating groups via the comb pusher

- Comb pusher equipped with anti-collision system

Cartoning system:

- Picking flat carton cuts from the magazine by an electric arm with vacuum suction cups

- Moving a group of products into a pre-formed carton using a servo motor-driven gripper

- Gripper equipped with a mechanism for squeezing the product

- A system supporting correct gluing equipped with vacuum suction cups

- Sensors detecting correct sealing of the carton

- Discharging finished cases from the cartoning section onto a short outtake conveyor

-

Case dimensions CASE WIDTH (mm) LENGTH (mm) HEIGHT (mm) Tray&Lid case 110-300 240-300 150-300 -

The process of packing into Tray&Lid boxes

Also see this

Tray Formers and Case Erectors

Packaging machines for forming four-flap cases and trays.

Cartoners

If you are looking for a reliable cartoner that will not let you down in the most crucial moments of your production you are in the right place. Radpak offers a wide range of top load and side loads cartoners for various industries.

Complete Packaging Lines

We offer modern and fully automated complete packaging lines, tailored to your needs.

Palletizing

We offer palletizing services that are fully integrated with our bulk cartoning systems, ensuring comprehensive and efficient final packaging services.

Vertical Packaging Machines

Radpak offers a wide range of vertical packaging machines that are designed for packing various types of products into pouches. Our impressive selection of VFFS machines makes Radpak an ideal partner for even most demanding applications.

Dosing systems

Our dosing systems that are integrated with Vertical Packaging Machines. Their task is to weigh a given dose of the product into a plastic bag.