RM-36ACD

The device allows the product to be packaged in a classically closed manner Doypack type packaging, with a string closure, the so-called zipper and popular sachets with three welded edges. Machine flexibility involves the use of a rotating jaw, thanks to which we can pack products into various types of bags.

-

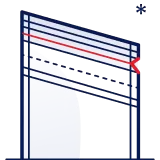

- Machine works in intermittent motion with heat sealable sealing jaws for PP films

- PLC controller

- Encoder for measuring without the print mark

- Color touch screen equipped with auto diagnostic and alarms

- Festo pneumatics with an air preparation station - the machine automatically detects too low pressure and automatically switches to STOP, displaying the appropriate alarm on the operator panel

- SICK photocell with microprocessor, for fast learning of marker color contrast

- Dangerous zones of the machine secured with limit switches on the front and side doors with automatic transition to STOP

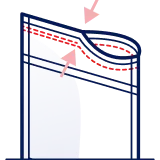

- - Automatic film tracking on the forming tube collar

- Festo pneumatic cylinder for closing the horizontal sealing jaws

- Mechanism for fast film connecting during reel change

- Speed up to 50 bags/min.

-

Dimensions BAG WIDTH (mm) LENGTH (mm) BOTTOM (mm) Doypack 150/340 185/340 50/100 Pillow bag 100/360 125/340 -

The process of packing into a doypack bag

Also see this

Tray Formers and Case Erectors

Packaging machines for forming four-flap cases and trays.

Cartoners

If you are looking for a reliable cartoner that will not let you down in the most crucial moments of your production you are in the right place. Radpak offers a wide range of top load and side loads cartoners for various industries.

Case packing

Case packing has never been easier. Discover the fascinating world of case packing systems by Radpak-fast, operator-friendly and reliable machines that will automate and grow your business.

Complete Packaging Lines

We offer modern and fully automated complete packaging lines, tailored to your needs.

Palletizing

We offer palletizing services that are fully integrated with our bulk cartoning systems, ensuring comprehensive and efficient final packaging services.

Dosing systems

Our dosing systems that are integrated with Vertical Packaging Machines. Their task is to weigh a given dose of the product into a plastic bag.